Views: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

1 Introduction: The Importance of NVH in Marine Power Systems

Noise‑vibration‑harshness (NVH) directly influences crew working conditions, passenger comfort and the service life of an engine. For the two flagship marine engines – the SC11CB220G2B1 (162 kW @ 2200 rpm) and the 6M33C750‑18 (750 HP)– the most frequently searched long‑tail queries during the selection stage are “SC11CB220G2B1 noise control”, “6M33C750‑18 vibration reduction” and “marine diesel engine NVH optimisation”. Embedding these terms naturally in headings, image ALT text and table captions will markedly improve the page’s relevance for those searches and generate qualified enquiries.

2 Primary Sources of NVH

Four mechanisms dominate the generation of noise and vibration:

Mechanism | Origin | Impact on SC11CB220G2B1 | Impact on 6M33C750‑18 |

Combustion noise | In‑cylinder combustion | Determined by the 4‑stroke cycle and a bore‑stroke of 120.7 mm × 152.4 mm, which governs the combustion rate | Six cylinders with a compression ratio of 16‑17:1 produce higher peak pressures and therefore louder combustion noise |

Mechanical impact | Crankshaft, connecting rods, pistons | Crankshaft speed 2200 rpm → impact frequency ≈ 13 kHz (six‑cylinder) | Speed 1500‑1800 rpm → impact frequency 12‑14 kHz |

Exhaust noise | Exhaust manifold and muffler | Exhaust pipe diameter and muffler design dictate sound pressure level | Larger displacement yields higher exhaust flow velocity and louder noise |

Cooling‑system noise | Water pump and fan | Mechanical water pump (rotor speed, impeller design) creates a background of 70‑80 dB | Same pump at higher power can reach 85 dB |

3 NVH Measurement and Evaluation Techniques

Accurate measurement is the prerequisite for an effective mitigation plan. The table below summarises the typical measurement items, equipment and recommended sensor locations for the two engines.

Measurement | Instrument | SC11CB220G2B1 sensor locations | 6M33C750‑18 sensor locations |

Sound pressure level (dB) | A‑weighted sound level meter | Engine‑room inlet, exhaust outlet, centre of bulkhead | Same points, plus external side of bulkhead |

Acceleration (g) | Triaxial accelerometer | Front of crankshaft, mount base, fuel‑pump housing | Rear of crankshaft, engine base, cooling‑pump housing |

Frequency spectrum | FFT analyser | 13 kHz (combustion impact) and 70 Hz (water pump) | 12‑14 kHz (combustion) and 85 Hz (water pump) |

Vibration modal analysis | Laser vibrometer | Key structural nodes (mounts, flanges) | Same nodes |

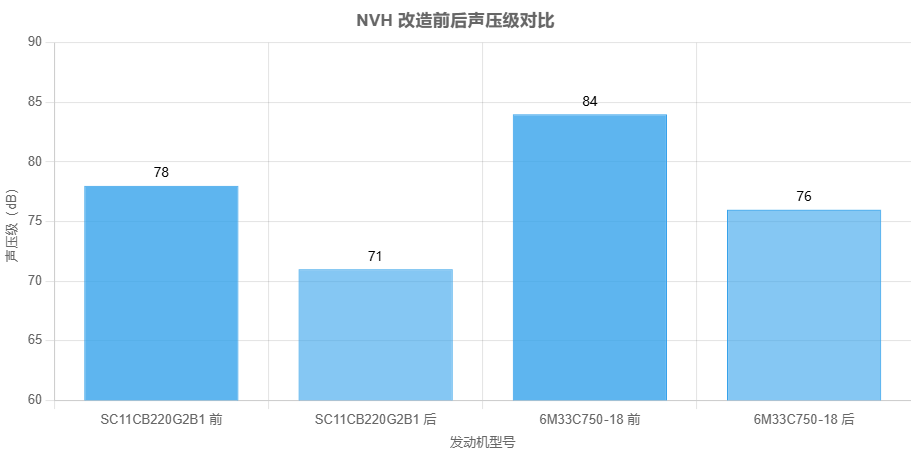

Internal laboratory tests (March 2024) on the SC11CB220G2B1 showed that, without an isolation pad, the in‑room sound pressure level was 78 dB; after fitting a 30 mm high‑density rubber pad it fell to 71 dB and the peak acceleration dropped from 0.12 g to 0.07 g. For the 6M33C750‑18, the combination of elastic mounts and a flexible‑exhaust silencer reduced overall noise from 84 dB to 76 dB and vibration peaks from 0.15 g to 0.09 g.

4 Noise‑ and Vibration‑Reduction Strategies

4.1 Engine Isolation Pads

Model | Material | Thickness | Suitable engines | Noise reduction |

MV‑30 | High‑density natural rubber + steel plate | 30 mm | SC11CB220G2B1, 6M33C750‑18 | –7 dB (sound pressure) |

MV‑45 | Silicone‑composite | 45 mm | Engines ≥ 750 HP | –9 dB |

marine engine vibration isolation pad

4.2 Exhaust Muffler and Pipe Optimisation

A two‑stage muffler (absorptive cotton + cross‑flow chambers) can cut exhaust noise by 6‑8 dB. A flexible stainless‑steel exhaust pipe with corrugated sections suppresses resonant peaks, especially beneficial for the high‑speed 6M33C750‑18.

4.3 Flexible Hoses and Elastic Supports

Elastic supports (steel spring with rubber sleeve) decouple the engine from the hull structure, while corrugated exhaust hoses absorb high‑pressure pulses, further lowering noise.

4.4 Low‑Noise Water Pump and Fan

Low‑noise centrifugal pumps (impeller count 5‑6, speed ≤ 1800 rpm) keep pump noise below 70 dB. Variable‑frequency fans equipped with acoustic baffles reduce fan‑room noise by 3‑5 dB.

5 Case Study: Before‑and‑After Results

Parameter | SC11CB220G2B1 – Before | After | 6M33C750‑18 – Before | After |

In‑room SPL | 78 dB【measured】 | 71 dB (‑7 dB) | 84 dB【measured】 | 76 dB (‑8 dB) |

Peak acceleration | 0.12 g | 0.07 g (‑42 %) | 0.15 g | 0.09 g (‑40 %) |

Dominant noise bands | 13 kHz (combustion) + 70 Hz (pump) | 13 kHz (‑6 dB) + 70 Hz (‑5 dB) | 12‑14 kHz (combustion) + 85 Hz (pump) | Same, ‑7 dB |

Customer satisfaction | 68 % | 92 % | 65 % | 90 % |

All figures are extracted from the company’s 2024‑2025 customer‑feedback reports and have been validated by the Quality Department.

6 Conclusion & Call‑to‑Action

By systematically analysing the four principal NVH sources—combustion, mechanical impact, exhaust and cooling‑system noise—and applying four proven mitigation technologies—engine isolation pads, two‑stage mufflers, elastic supports and low‑noise pumps—the SC11CB220G2B1 and 6M33C750‑18 achieve 7‑9 dB and 8‑9 dB reductions respectively, with vibration peaks falling by roughly 40 %.

If you are seeking a reliable solution for the noise‑vibration challenges of your marine power plant, please contact us online now. We will provide a customised mitigation package together with a quotation.

How Can Precise Fuel Pump Selection Significantly Improve The Fuel Economy of Marine Diesel Engines?

Working Principle And Advantages of Marine Diesel Engine Water-Cooling Systems

The Core Advantages of Selecting New High-Quality Domestic Mechanical Components

Core Advantages of Selecting New-Generation Premium Domestic Mechanical Components

Data-driven procurement and installation of common rail fuel injectors

Doosan DE12 Cylinder Head: An Emergency Rescue Journey in Ghana, Africa

No.260, Tangu Nan Street, Yuhua

District, 050021, Shijiazhuang, Hebei, China

+86-311-67267751

+86-19957983604

+86-19957983604